Heat Reflective Roof Coating: Does It Really Reduce Indoor Heat?

Can roof coating lower your home temperature? We explain how reflective coatings work, typical results, and whether it's worth the investment.

The Promise of a Cooler Home

Malaysia sits almost directly on the equator, and our roofs absorb intense solar radiation for most of the year. On a typical sunny afternoon, a dark-coloured concrete or metal roof can reach surface temperatures of 60 to 70 degrees Celsius. That heat radiates downward into your home, making your living spaces uncomfortable and forcing your air conditioning system to work harder than it should.

Heat reflective roof coatings claim to solve this problem by reflecting a significant portion of the sun’s energy back into the atmosphere rather than absorbing it into your roof. But do they actually work? And if so, are they worth the investment? This guide examines the science, the real-world results, and the practical considerations for Malaysian homeowners.

How Heat Reflective Coatings Work

To understand reflective coatings, you need to understand how heat enters your home through the roof. Solar radiation hits your roof in three forms: visible light, ultraviolet (UV) light, and infrared radiation. A conventional dark roof absorbs most of this radiation and converts it to heat, which then conducts through the roof structure and radiates into the rooms below.

Heat reflective coatings work in two ways.

Solar reflectance. The coating reflects a high percentage of incoming solar radiation back into the atmosphere. A good reflective coating can reflect 80 to 90 percent of solar energy, compared to a standard dark roof which may reflect only 5 to 15 percent.

Thermal emittance. Whatever heat the roof does absorb, the coating helps release it quickly back into the atmosphere rather than conducting it downward into the building. High thermal emittance means the roof surface cools faster.

The combination of high solar reflectance and high thermal emittance is what creates the “cool roof” effect. The roof simply does not get as hot, so less heat enters your home.

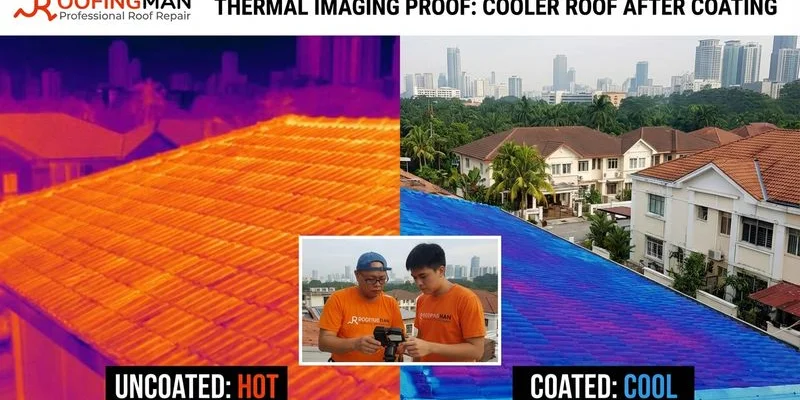

Real Temperature Reduction Results

The question most Malaysian homeowners ask is straightforward: how many degrees cooler will my home actually be?

Based on field measurements in Malaysian conditions, here are the typical results you can expect.

Roof surface temperature reduction: 10 to 20 degrees Celsius. This is where the effect is most dramatic. A roof that previously reached 65 degrees Celsius in afternoon sun may only reach 45 to 50 degrees with a reflective coating applied.

Ceiling temperature reduction: 5 to 10 degrees Celsius. The heat that conducts through the roof structure is significantly reduced, resulting in a noticeably cooler ceiling surface.

Indoor air temperature reduction: 3 to 7 degrees Celsius. This is what you actually feel. The exact reduction depends on factors including your roof type, insulation, ventilation, and the floor area of the room below.

Air conditioning savings: 15 to 30 percent reduction in cooling energy. For homes that run air conditioning for several hours daily, this translates to meaningful electricity bill savings. At current Malaysian electricity rates, this can amount to RM50 to RM200 per month for a typical terrace house, depending on usage patterns.

These results are not theoretical. Multiple studies conducted in tropical climates similar to Malaysia’s have confirmed reductions in this range, and our own experience with hundreds of roof coating applications in Malaysian homes aligns with these figures.

Types of Heat Reflective Coatings

Not all reflective coatings are created equal. The main types available in Malaysia are as follows.

Acrylic Elastomeric Coatings

The most common type for residential use. These are water-based coatings that form a flexible, waterproof membrane over the roof surface.

Pros: Good reflectivity (typically 80 to 85 percent). Flexible — can bridge small cracks. Waterproofing properties. Easy to apply. Available in white and light colours.

Cons: Needs reapplication every 5 to 7 years. Can peel if surface preparation is poor. Performance degrades as the surface gets dirty.

Silicone-Based Coatings

A premium option that offers superior durability and weather resistance.

Pros: Excellent UV resistance. Longer lifespan (8 to 12 years). Superior water resistance — does not become brittle. Maintains reflectivity longer.

Cons: Higher cost. Requires specific surface preparation. Not paintable once applied.

Ceramic-Infused Coatings

These coatings contain microscopic ceramic particles that enhance both reflectivity and insulating properties.

Pros: Highest reflectivity ratings (85 to 92 percent). Additional insulating effect from ceramic particles. Long lifespan. Excellent durability.

Cons: Most expensive option. Requires professional application. Limited colour choices.

Aluminium-Based Reflective Coatings

Traditional reflective coatings that use aluminium flakes to create a reflective surface.

Pros: Good reflectivity. Lower cost. Well-suited for metal roofs. Quick application.

Cons: Shorter lifespan (3 to 5 years). Less effective waterproofing. Metallic appearance may not suit all homes.

Best Roof Types for Coating

Heat reflective coatings can be applied to most roof types, but the benefits vary depending on the roof material and construction.

Flat concrete roofs. These benefit the most from reflective coatings. Concrete absorbs and retains enormous amounts of heat, and the flat surface allows easy, uniform application. If you have a concrete flat roof — common on Malaysian commercial buildings and some residential extensions — reflective coating should be a high priority.

Metal roofs. Zinc and aluminium roofing sheets get extremely hot in direct sun. Reflective coatings significantly reduce metal roof temperatures and also help with the noise issue — a coated metal roof is noticeably quieter during rain.

Clay and concrete tile roofs. These are the most common residential roof type in Malaysia. Coatings can be applied to tiles, though the irregular surface requires more coating material and careful application. The temperature reduction is still significant, though slightly less dramatic than on flat surfaces.

Polycarbonate and translucent roofing. Reflective coatings are not suitable for these materials, as they would block the light transmission that is the reason for choosing translucent roofing in the first place. Heat-rejecting films or tinted replacements are better options for these roofs.

Cost vs Electricity Savings

Here is a practical cost-benefit analysis for a typical Malaysian terrace house.

Application cost: RM2,000 to RM6,000, depending on roof size, type, and coating selected. A standard double-storey terrace with a roof area of 80 to 100 square metres typically falls in the RM3,000 to RM4,500 range for a quality acrylic elastomeric coating.

Monthly electricity savings: RM50 to RM200, depending on your current air conditioning usage. Homes that run air conditioning heavily will see larger savings.

Payback period: Typically 18 to 36 months. After the payback period, the electricity savings are pure profit for the remaining life of the coating.

Additional value: Beyond electricity savings, a cooler home is simply more comfortable. Rooms are more pleasant even without air conditioning, and the reduced thermal stress on your roof extends its overall lifespan.

The Application Process

Professional application of heat reflective coating follows a specific process to ensure maximum performance and longevity.

- Surface inspection. The roof is inspected for cracks, damage, and areas that need repair before coating.

- Cleaning. The roof surface is pressure-washed to remove dirt, algae, and loose material. This step is critical — coating applied over a dirty surface will not bond properly.

- Repairs. Any cracks, gaps, or damaged areas are repaired and sealed before coating.

- Primer application. A bonding primer is applied to ensure the coating adheres properly to the roof surface.

- Coating application. The reflective coating is applied in two or three coats, with drying time between each coat. Total application typically takes one to two days.

- Curing. The coating needs 24 to 48 hours to fully cure before it delivers its full reflective performance.

Is It Worth the Investment?

For most Malaysian homeowners, heat reflective roof coating is one of the most cost-effective home improvements you can make. The combination of lower electricity bills, improved indoor comfort, and extended roof life makes it a smart investment, especially for homes with flat concrete roofs or metal roofing that absorb significant heat.

The key is to choose a quality coating, ensure proper surface preparation, and have it applied by experienced professionals. A properly applied reflective coating will deliver measurable results from the very first sunny day, and continue performing for years to come.

Tags

Need Professional Help?

If you're dealing with this issue, our team can help. Get a free inspection and honest quote.